- TOSIZE.dk

- Wood and sheet material

Melamine

A furniture panel is a 'ready-to-use' sheet material finished with a melamine layer on the top and bottom. A melamine layer or melamine coated top layer is a thin pressed, plastic layer. Furniture panels, also known as furniture boards, therefore do not need to be finished. This panel material is therefore very popular in interior construction. They are ideal to use for furniture, as shelves or to replace your old kitchen doors.

Others were also looking for:

Order cut-to size sheet material with an melamine top layer

Order cut-to-size furniture panels online

Buy custom-made furniture panels easily online. We have different brands and designs available. We understand that the many options make it hard to choose. Using our filters, you can easily find the look that suits your application. You can find a suitable wood type or thickness for every job!

Our decorative board materials have a strong and hard melamine layer (plastic). This gives the wood panels an attractive appearance and makes this panel material able to withstand rough handling. Because it is customary to make furniture panels from fibreboard, it is not only a practical, but also a durable product. This is because fibreboards consist of compressed wood chips, which are a waste product.

What are furniture panels?

Furniture panel is a collective term for sheet material consisting of a base (or backing) finished with one or two top layers. The core, also called middle layer, can be made of different materials. The top layer ensures a unique look, a durable product and/or better properties of the finished material. For the base of a furniture board, wood with a lower visual quality is often used, to compensate for the scarcity of real wood. This does not mean that the board is of lower quality, but only that the wood with, for example, a different colour is added in the middle. This has several advantages: it keeps the material affordable and reduces waste.

Ordering fully finished sheet material

When looking for finished board material, you generally end up in two categories: melaminated board material and veneered board material. As a substrate, or base, MDF, chipboard or another strong fibreboard is often chosen. The difference between these carriers is generally minimal. Are you looking for a specific texture, or colour? Then go for your favourite top layer and don't let the material's carrier influence you.

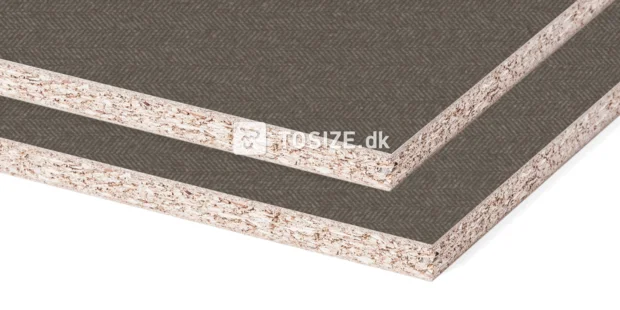

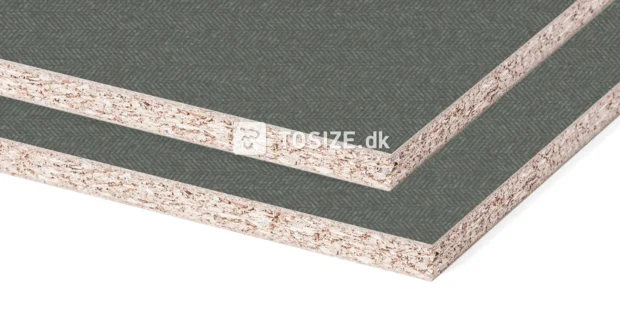

Because of the texture in the top layer, furniture panels are ideally suited for decorative purposes: it combines the strong properties of the substrate with a top layer of your choice. This is why furniture panels are also known as 'decorative chipboard' or 'decorative panels'. Decorative chipboard, also known as furniture panel, is an easy-to-assemble board material with a chipboard core finished on one or both sides with a melamine top layer.

Melaminated board material

The advantage of melaminated board material over veneered material is that it is immediately ready for use: there is no need to finish it! This makes the product ideal for use. A melamine top layer is made of paper fibres fused together with a melamine resin. This creates a hard plastic top layer. This top layer is applied to the backing. A melamine top layer has a high density, which also gives it its hard and strong properties. A melamine top layer is water-repellent and to some extent heat-resistant. In addition, this board material is easy to wipe off and keeps well clean. The material is therefore often chosen for use in interiors.

Melaminated chipboard is available in various colours, textures, sizes and thicknesses. The material and pattern is often computer-generated, which is why melamine-faced board material does not vary in colour. There is always the same look, with a fixed colour scheme. Techniques are now very advanced, making the plastic wood look more and more like real wood and the big advantage: no protective coating needs to be applied. Melaminated material is a relatively new technique within the wood world compared to, for example, veneered board material. With our professional saws, we ensure that the board material is accurately cut to size and immediately ready for use. Order ready-to-use board material cut to size easily online. This way, you only have to assemble the panel material.

When you cut melamine-laminated board material to size, you will see that only the top and bottom sides have the top layer of melamine. On the sides, you will see the carrier material (often chipboard or MDF). To finish these sides nicely, there is ABS tape. This is available in the same colour and texture as the top layer, to create a nice whole after finishing the edges.

When you start processing melaminated material yourself, the top layer may splinter. This is because it is a very thin and hard layer. Have your melamine material professionally cut to size by us and there will be much less chance of the top layer splintering!

In brief, the advantages of melamine faced board material once again:

- Ready to use immediately

- Strong and water-repellent

- Fixed colour

Chipboard, MDF or solid furniture panels?

Furniture panels can have different carriers. The technical specifications depend on the carrier. But which is the right choice? We explain the advantages of each material.

Decorative chipboard

Chipboard is one of the most popular materials when it comes to melamine-coated decorative panels. You could almost say it is the standard panel material to which a melamine top layer is applied. That is why it is also known as 'decorative chipboard'. Chipboard has a number of important properties:

- It is ecologically a sustainable choice

- It is relatively cheap

- It is a light a versatile material

- It is easy to saw and screw.

The combination of these reasons means that in many cases, particleboard is chosen for melaminated board material. We use high-quality chipboard, but the material remains compressed chips, which makes it ultimately less strong than, for example, MDF.

Decorative MDF

We are all familiar with the properties of MDF: a compressed fibreboard. As with chipboard, the quality of the MDF depends on the pressing pressure and pressing time. We only cut high-quality MDF. Whereas chipboard used to be the standard backing for melaminated furniture panels, MDF is gaining ground due to its strong, stable and high-quality properties. Due to its homogeneous structure, it is less likely to blunt your sawing and drilling equipment and is easy to assemble. Are you looking for veneered material? Then the standard carrier is MDF or, traditionally, solid panels. Because veneers are more fragile than melaminated material, MDF is always chosen as the carrier for these top layers.

Solid panels

Are you looking for furniture panels with a wooden look? Then you may also end up with solid panels. Or solid panels with a veneer top layer. In the wood industry, solid is often used as a catch-all term. A truly solid panel, consisting of a single piece, is very expensive. In addition, there is scarcity in the industry, so new wooden panels are assembled in a creative way. This keeps the material affordable, accessible and creates the same look and feel as a solid panel. Wood panels with a solid core are one of the oldest types of veneer panels. Wooden slats are used for the core and the top layer is then finished with a veneer. The quality and price strongly depend on the visual quality of the veneer, the thickness of the top layer and, whether it is one- or two-sided finished.

The properties of decorative furniture panels

Above, you were able to read about the difference between melaminated and solid boards. The different types of supports have also been covered. But besides these properties, there are also some practical properties that can apply to your DIY projects.

Standard furniture panels

The most common variant of available furniture panels is with a chipboard or MDF backing. Curious about the properties of that panel material? Our tip: Then read more about the properties of the carrier. That way, you can quickly find out whether the board material is suitable for your next DIY project.

Furniture panels with Water-resistant properties

If you see the type V313 or the term Water-resistant passing by the product, then the core of the carrier is Water-resistant. The gluing, pressing pressure and pressing time of the composition of fibreboards add extra Water-resistant properties to the board material. However, always bear in mind that the top layer is not necessarily Water-resistant. Curious about the properties? Check out the properties of Damp-proof MDF or Moisture Proof chipboard.

Fire-retardant panels

Panels with fire retardant properties can also be finished with a melaminated or veneered top layer. However, this variant is a lot scarcer than standard or moisture-resistant furniture panels. Check out the possibilities in our webshop!

Furniture panels and brands

Furniture panels can be ordered in several variants and thicknesses and with a wide variety of structures. Don't be put off by the many brand names such as UNILIN Evola, Pfleiderer, Egger or other major brands. The decors are similar in colour, texture and quality. We have several brands and only supply high-quality decorative panels with a unique look.

View our range of Melamine sheet material here:

Ordering cut-to size UNILIN Evola furniture panels

With UNILIN Evola's original designs and textures, you can create a DIY project quickly and easily. Inspired by fashion, art and unspoilt nature, the UNILIN Evola collection offers enormous creative freedom. Would you like to order UNILIN Evola decorative sheet material online? Check out all available decors.

Cut- to size furniture panels from Pfleiderer

Like UNILIN Evola, Pfleiderer also supplies decorative chipboard with a wide variety of melamine decors and textures. Order melamine faced board materials easily and quickly online. That's really convenient.

Various furniture panel products

Besides the UNILIN Evola and Pfleiderer range, we also supply other custom-made furniture panels from small and large brands, including from:

- Querkus

- Decospan

- Nørdus

- Shinnoki

- Innovus

- FINSA

Read more about the different brands we offer here.

Furniture panels as an interior application

Melaminated or decorative chipboard is widely used for making furniture. It is a versatile product that can be used for many purposes. Think of desk tops, cupboards, kitchen, bookcases or shelves. Furniture often has a large surface area and therefore takes a long time to finish. By using melamine-coated board material, you no longer need to paint the board material and you ensure that everything looks smooth. With the various decors and textures available, there is a suitable sheet material for every job.

DIY projects with furniture panels

Need inspiration or just curious about what you can achieve with decorative chipboard? Then take a look at our DIY and interior blog. Many others have gone before you by ordering made-to-measure chipboard. Perhaps your dream furniture is already among them and you can adopt the shopping list in no time.

Alternatives to furniture panels

Is furniture panel not what you're looking for after all? Check out our whole range of sheet material; everything can be cut or milled to the millimetre and find the ideal type of wood for your next project.